Application of W9-19 high temperature centrifugal fan:

It is suitable for transporting weakly corrosive and unnatural gases at 250 ℃ -950 ℃ , the dust content of the gas and the concentration of hard particles are not more than 150mg/ m3 . It is generally used for the exhaust gas of various heating furnaces. W9-19 high-temperature fan is a boiler matching fan designed to overcome the phenomenon of insufficient draft caused by adding dust removal equipment and waste heat utilization equipment to the boiler, positive pressure in the furnace, etc., which affect the combustion and normal operation of the boiler.

W9-19 high temperature centrifugal fan type:

(1) The fan is made of single suction, and the machine numbers are NO.5, 6.3, 8, and 9 .

(2) The fan can be made into two types of left-hand rotation or right-hand rotation. Looking at the fan from the transmission part , if the impeller rotates clockwise, it is called right-hand rotation and is represented by "right"; counterclockwise rotation is called left-hand rotation, and is represented by "" Left" means.

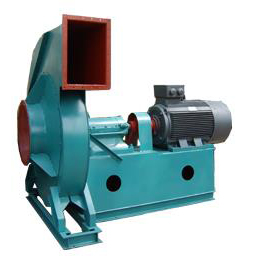

W9-19 high temperature centrifugal fan structure:

The fan is composed of impeller, casing, air inlet, transmission group and other components, and is equipped with an adjusting door.

(1) Impeller: There are 16 forward curved blades, the material is 16Mn

(2) Shell: welded with steel plates to form a whole volute . There is a dust-cleaning door on the worm plate, which is convenient for removing the dust accumulated on the blades and inside the casing.

(3) Air inlet: It is made into a convergent and streamlined overall structure, and is fixed with bolts and the front cover.

(4) Transmission group: It is composed of main shaft, bearing box, pulley and so on.

W9-19 high temperature centrifugal fan parameter table

machine number | Rotating speed | Full pressure | flow | electric motor | ||

r / min | Pa | m3/h | model | Power KW | ||

4.5 | 2900 | 1838-1815 | 1174-1995 | Y100L-2 | 3 | |

1744-1584 | 2269-2817 | Y112M-2 | 4 | |||

5 | 2500 | 1704-1730 | 1388-3331 | Y100L-2 | 3 | |

1680-1479 | 4610-7837 | Y112M-2 | 4 | |||

7.1 | 2900 | 4824-4769 | 4610-7837 | Y200L1-2 | 30 | |

463-4296 | 8912-11064 | Y200L2-2 | 37 | |||

8 | 2600 | 6002-6075 | 5912-8671 | Y200L2-2 | 37 | |

5932-5343 | 10051-14190 | Y225M-2 | 45 | |||

9 | 1450 | 1593-1616 | 4695-6886 | Y160M-4 | 11 | |

1576-1409 | 7981-11267 | Y160L-4 | 15 | |||

11.2 | 1450 | 3223-3262 | 9048-13270 | Y225S-4 | 37 | |

3185-2869 | 15381-21714 | Y225M-4 | 45 | |||

12.5 | 1450 | 5170-5109 | 12578-21383 | Y280S-4 | 75 | |

4961-4598 | 24317-30187 | Y280M-4 | 90 | |||

17 | 1450 | 8023-8170 | 63279-78048 | Y400-4 | 400 | |

8117-7704 | 92806-122344 | Y400-4 | 500 | |||

7424-7143 | 137102-151870 | Y450-4 | 630 | |||

18 | 1450 | 8995-9159 | 75116-92647 | Y400-4 | 450 | |

9100-8637 | 110166-145228 | Y450-4 | 630 | |||

8323-8009 | 162748-180279 | Y450-4 | 800 | |||