10-20 centrifugal fan use

The fan is generally used in metallurgy, petroleum, chemical industry, food, building materials industry and other departments for high-pressure forced air or material and material pneumatic conveying. Suitable for conveying air and non-corrosive, non-explosive, non-tender, non-viscous gas. The temperature of the medium is generally not more than 50℃ and the maximum is not more than 80℃. The dust and hard fine particles contained in the medium are not more than 150mg/m3.

10-20 centrifugal fan form

1. The fan is made of single suction, machine number is No.8a, 8, 8b, 8.5A, 8.5, 8.5B, 9a, 9, 9b, a total of nine kinds.

2. The outlet position of the fan is represented by the outlet Angle of the housing. "Straight" and "reverse" can be made into 0°, 90°, 180° stop Angle.

3. The fan can be made into two types of clockwise rotation or counterclockwise rotation. From the driving part to face the fan, such as the impeller clockwise rotation known as clockwise rotating fan, to "cis"; Counterclockwise rotation, called counterclockwise rotation fan, represented by "inverse".

4. The transmission mode of the fan adopts D type coupling direct transmission.

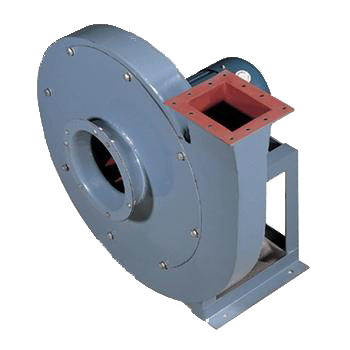

10-20 type centrifugal fan structure

The fan is composed of impeller, housing, air inlet, transmission part and so on.

1. Impeller: The long and short blades have 12 forward-bending blades, which are uniformly welded between the four arc-shaped wheel cover and the flat-shaped wheel, and the flow passage composed of the bladeless diffuser. The material is Q345(16Mn).

2. Shell: The steel plate is welded into the cochlear putamen.

3. Transmission part: composed of spindle, bearing box, coupling and so on

4. Air inlet: The air inlet of the converging and dispersing type is made into an overall structure, which is fixed on the front cover plate with bolts.