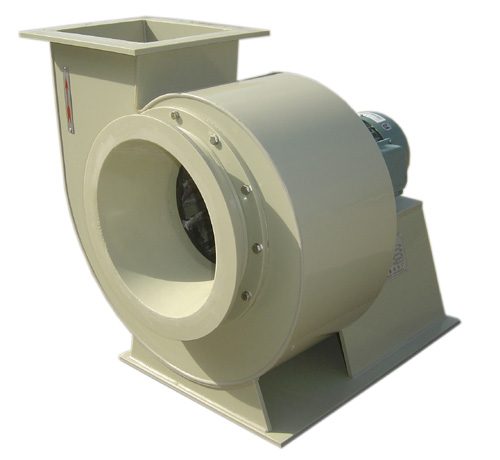

F9-28 Type I Anti-corrosion Centrifugal Fan Application:

F9-28 I-type anti-corrosion centrifugal fan is generally used in forging and high-pressure forced ventilation, and is widely used in material transportation, and can be used to transport air and five corrosive, non-self-igniting, and non- viscous gases. The temperature of the conveying medium generally does not exceed 80 degrees Celsius, and the dust and hard fine particles contained in the ring are not more than 150 mg/cubic. The fan can also be used as a high-temperature fan used in special occasions such as cement cellar decomposition work and steel smelting.

F9-28 I type anti-corrosion tail gas centrifugal fan type:

1. The fan is available in two types: single-suction and double-suction. There are 20 machine numbers including No4, 4.5, 5, 5.6, 6.3, 7.1, 8, 9, 10, 11.214, 16, 17, 18, 20, 21, 22, 23, and 24.

2. The fan can also be made into two types of right-handed or left-handed; if the impeller rotates clockwise when viewed from the front of the motor (or main shaft), it is called a clockwise fan, which is represented by "shun"; if the impeller rotates counterclockwise, It is called reverse fan, and it is represented by "reverse".

3. The outlet position of the fan is represented by the outlet angle of the casing, "left" and "right" can be made into six angles of 0 degree, 45 degree, 90 degree, 135 degree, 180 degree and 225 degree.

4. The transmission mode of the fan is A type (machine number 4-6.3), D type (machine number 7.1-16) and F type.

F9-28 I type anti-corrosion tail gas centrifugal fan structure:

No.4~6.3 of the fans are mainly composed of impellers, casings, air inlets, brackets, etc. No.7.1~24 of fans are composed of impellers, casings, air inlets, transmission groups , etc. F-type transmissions are mainly composed of impellers, It is composed of casing, air intake box, transmission group , etc. The fan can also be equipped with an adjustable door according to the needs of users. The impeller of 1.9-28I fan has 16 long blades and 16 short blades.

2. The casing is welded with ordinary steel plates to form a volute as a whole. For high-temperature fans, heat-resistant materials can be selected according to the temperature. The casing can also be made into splits.

3. The air inlet is made into a convergent and streamlined overall structure, which is fixed with bolts and the front cover plate.

4. The transmission group is composed of main shaft, bearing box, coupling and so on.

The flow range of the fan is 2,200 cubic meters - 300,000 cubic meters/h (single suction), 600,000 cubic meters/h (double suction), and the pressure range is 350kg/ square - 200Kg/square

F9-28 I type anti-corrosion centrifugal fan parameters:

machine number no | transmission Way | Rotating speed r/ min | Full pressure Pa | flow m3/h | internal efficiency ﹪ | Internal power KW | required power KW |

motor |

12.5

|

D

|

960

| 5164 | 22200 | 81.5 | 31.54 | 37.8 |

Y280S-6 45KW |

5158 | 24980 | 82.6 | 34.92 | 40.9 | ||||

5101 | 27760 | 82.6 | 38.36 | 45.1 | ||||

5040 | 30590 | 81.0 | 41.80 | 49.2 | ||||

4917 | 33300 | 81.1 | 45.32 | 53.2 |

Y315S-6 75KW | |||

4884 | 36093 | 80.0 | 48.87 | 57.0 | ||||

4799 | 38870 | 78.3 | 52.31 | 61.5 | ||||

4689 | 41,732 | 76.4 | 55.58 | 65.8 | ||||

14 |

D |

960 | 5530 | 34289 | 81.5 | 55.89 | 69.02 |

Y325S-6 75KW |

5528 | 35107 | 82.6 | 61.73 | 72.13 | ||||

5460 | 39076 | 82.6 | 67.84 | 74.09 | ||||

5309 | 42943 | 82.0 | 73.64 | 87.37 |

Y315M-6 110KW | |||

5288 | 46832 | 81.1 | 80.21 | 94.68 | ||||

5181 | 50743 | 80.0 | 85.92 | 102.7 | ||||

5063 | 54681 | 78.3 | 92.74 | 107.8 | ||||

4998 | 59303 | 76.4 | 99.05 | 110.3 |

machine number no | transmission Way | Rotating speed r/ min | Full pressure Pa | flow m3/h | internal efficiency ﹪ | Internal power KW | required power KW |

motor |

16 |

D. |

960 | 7335 | 46580 | 81.5 | 110.5 | 129.3 |

Y355M-6 160KW |

7318 | 52381 | 82.6 | 122.0 | 142.8 | ||||

7229 | 58277 | 82.6 | 133.7 | 156.6 | ||||

7121 | 64098 | 82.0 | 146.6 | 170.4 |

Y355M-6 250KW | |||

7001 | 69903 | 81.1 | 157.5 | 184.5 | ||||

6864 | 75701 | 80.0 | 169.2 | 198.2 | ||||

6709 | 81503 | 78.3 | 181.4 | 212.6 | ||||

6596 | 87425 | 76.4 | 194.4 | 227.8 | ||||

17

|

D

|

960

| 7703 | 55933 | 81.5 | 148.8 | 170.7 |

Y355M-6 220KW

|

7728 | 62952 | 82.6 | 164.6 | 188.9 | ||||

7630 | 69931 | 82.6 | 179.4 | 207.6 | ||||

7493 | 76901 | 82.0 | 192.1 | 220.1 | ||||

7381 | 83872 | 81.1 | 209.3 | 243.2 |

Y355M-6 280KW | |||

7291 | 90995 | 80.0 | 225.7 | 262.8 | ||||

7106 | 97872 | 78.3 | 242.4 | 283.3 | ||||

6910 | 104831 | 76.4 | 258.1 | 303.8 |

machine number no | transmission Way | Rotating speed r/ min | Full pressure Pa | flow m3/h | internal efficiency ﹪ | Internal power KW | required power KW |

motor |

18

|

D

|

730

| 5517 | 50594 | 81.5 | 86.17 | 100.8 |

Y355S-8 185KW |

5505 | 57193 | 82.6 | 95.42 | 111.6 | ||||

5442 | 63692 | 82.6 | 104.6 | 122.1 | ||||

5357 | 69795 | 81.0 | 114.0 | 133.2 | ||||

5278 | 76692 | 81.1 | 123.8 | 144.9 | ||||

5175 | 82390 | 80.0 | 132.9 | 155.5 | ||||

5061 | 88689 | 78.3 | 142.6 | 166.9 | ||||

5001 | 94989 | 76.4 | 152.8 | 178.7 | ||||

20 |

D |

730 | 6300 | 69170 | 81.5 | 146.1 |

Y355S-8 220KW

| |